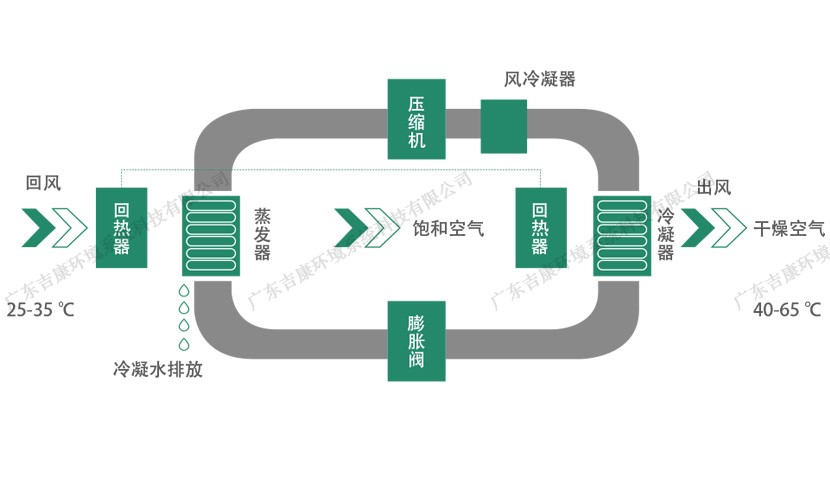

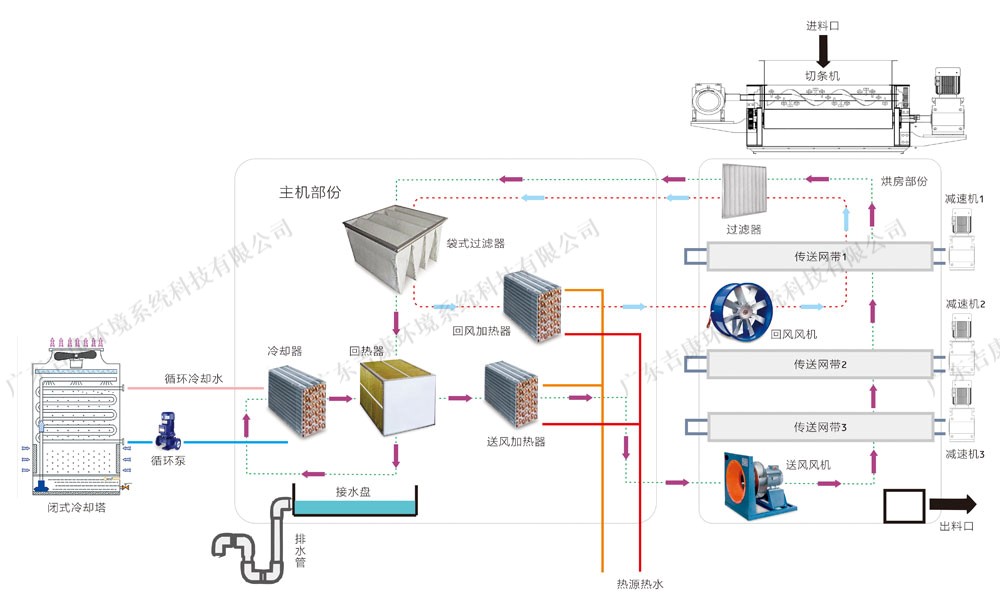

通过高温热源与除湿冷源共同作用产生 40~60℃极干空气,穿透污泥动态传输网带将污泥水分蒸发,营造低温节能的烘干环境;

吸水后的空气通过经济闭式循环,回到除湿冷源并冷凝出低温液态水排出的过程。

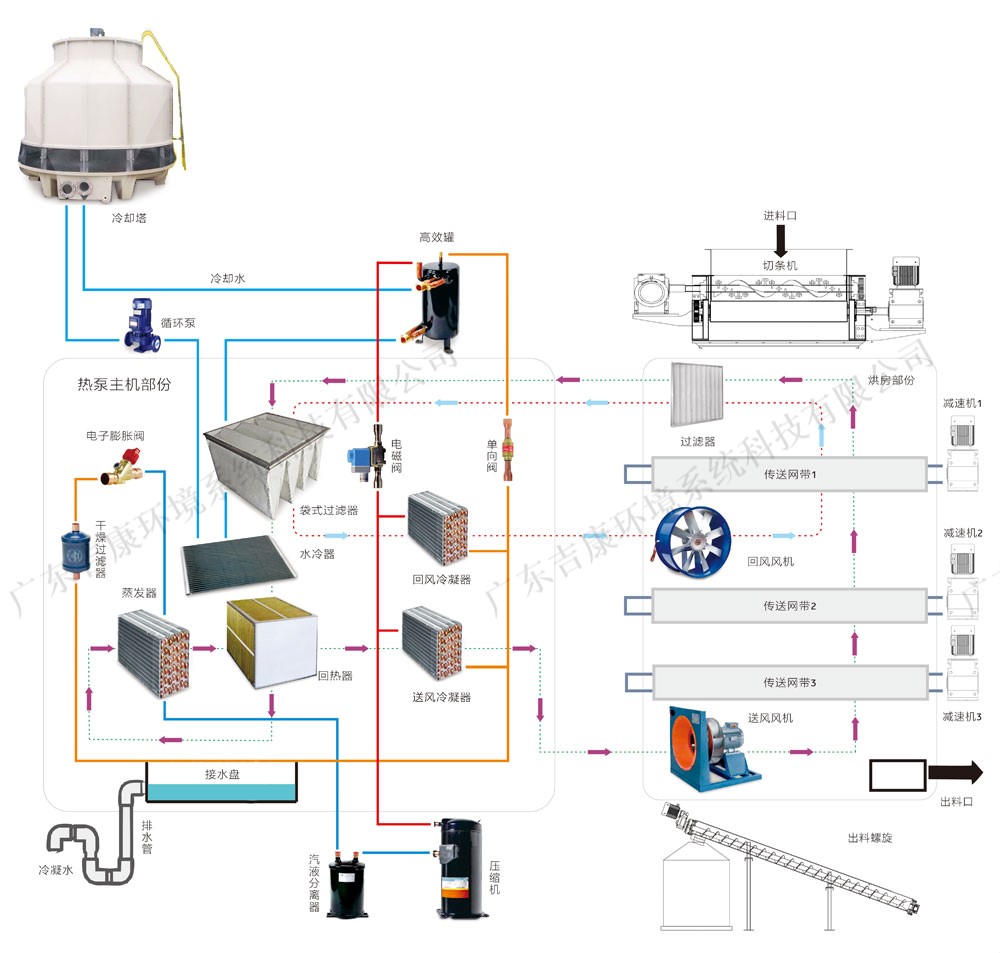

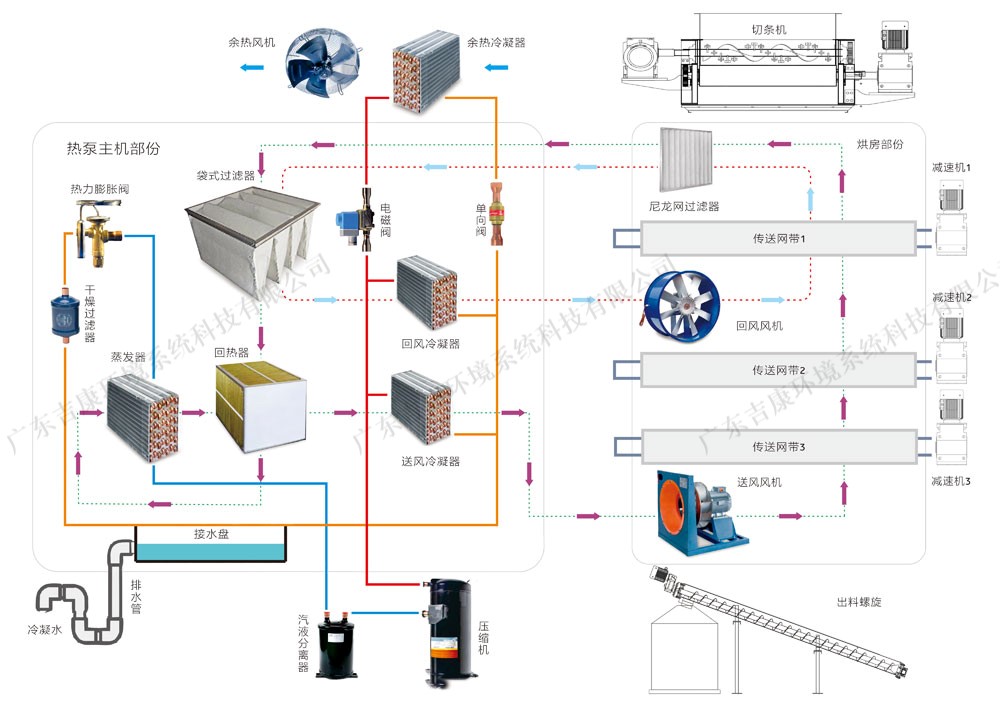

低温干化设备按能源分,可以分成电能型污泥低温干化与余热型污泥低温干化两种。电能型污泥低温干化主要以压缩机为动力源提供高温热源与除湿冷源,余热型污泥低温干化主要以现有废热产生的蒸汽或高温热水为高温热源、现有冷却塔冷却水或污水为除湿冷源。低温干化设备整体精简,一体化设计,智能可控;较传统的热干化方式,高效节能,无需额外废气粉尘处理。

Through the joint action of high temperature heat source and dehumidification cold source, 40 ~ 60 ℃ extremely dry air is produced, which penetrates the sludge dynamic transmission network belt to evaporate the sludge moisture, creating a low-temperature and energy-saving drying environment; after absorbing water, the air returns to the dehumidification cold source and condenses low-temperature liquid water for discharge through the economic closed cycle.

According to energy, low temperature drying equipment can be divided into two types: low temperature drying of electric sludge and low temperature drying of waste heat sludge. The low-temperature drying of electric sludge mainly uses the compressor as the power source to provide high-temperature heat source and dehumidification cold source, while the low-temperature drying of waste heat sludge mainly uses the steam or high-temperature hot water generated by the existing waste heat as the high STX temperature heat source, and the cooling water or sewage from the existing cooling tower as the dehumidification cold source. Compared with the traditional heat drying method, the low-temperature drying equipment is more efficient and energy-saving, without additional waste gas and dust treatment.